Special Features

Stabilizing the leveling of rolling table

The relative leveling between “rolling table“ which supports rolling by mounting work and lower edge roll affects the process of rolling rings greatly. This leveling operation used to be done by manually bolt adjusting method in the past.

However, this method takes long, work efficiency is not good, and it was a problem to gain a stable quality.

In our machine, a gradient plate for leveling is moved back and forth by hydraulic from operator room, clamping mechanism is installed, and thereby the remote control operation is enabled.

Fully adopting AC motor

The motor for edge roll which is capable of changing speed used to be DC motor in the past but It was difficult to procure in general and the maintenance was not easy.

We made AC motor as the standard as its inverter control method is good in control and applicability.

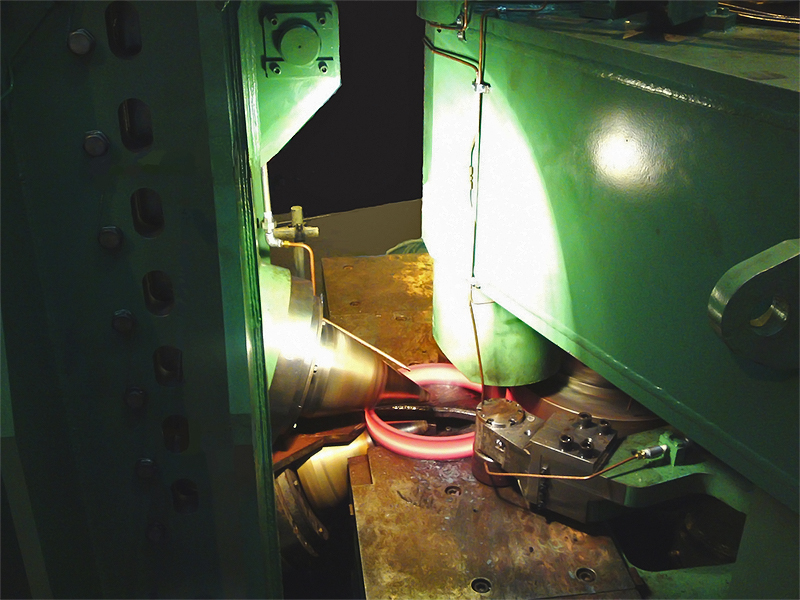

Adopting forced driven method of top and bottom edge rolls for all the machine type

We adopted the forced driven method for top and bottom edge rolls to prevent swelling or rolling up generated in rolling with ring rolling mill and lifting often generated in initial stage of rolling. It enables to improve the circularity, suppress the generation of fishtail or depression at the edge of rings, and thereby reduce the allowance.

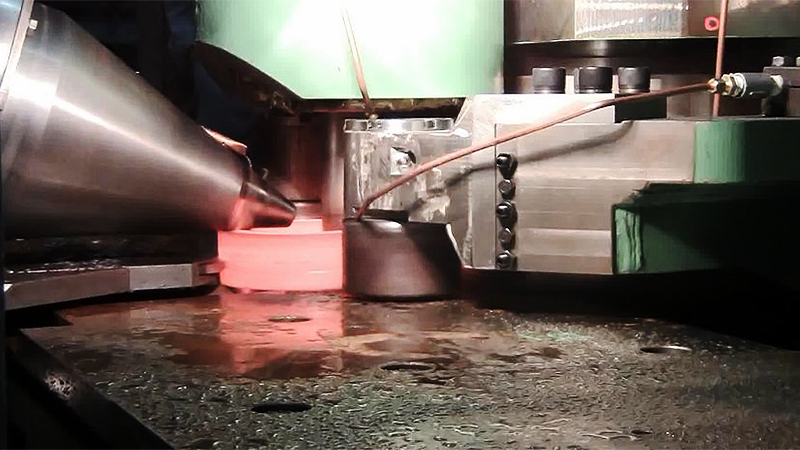

Easy to replace change edge rolls

A special mechanism is installed to the edging roll; the edge rolls are installed to bearing sleeves by taper engagement so that only the edge point part is changed, which enables to attach and detach by a few minutes.

Also, the angle of edge rolls is 40 to 45° so that it stands axial load sufficiently.

Also, you can decrease the time for replacing, secure the safety of operation, and reduce the material cost by adopting separate type edge roll (In the process of applying its patent.) by which you can replace top parts only .

Centering roll control to gain circular ring

New control system in which the pressure and position control are built enables to always maintain rings symmetrical to axis during rolling. This ensures superior circularity.

Unitizing of main axis part

The structure for main axis part in which main roll is built is made into an integrated unit with top and bottom bearing and coupling, which is easy to attach and detach. You can decrease the time for changing main roll and operate. The top shim enables to adjust level easily too.

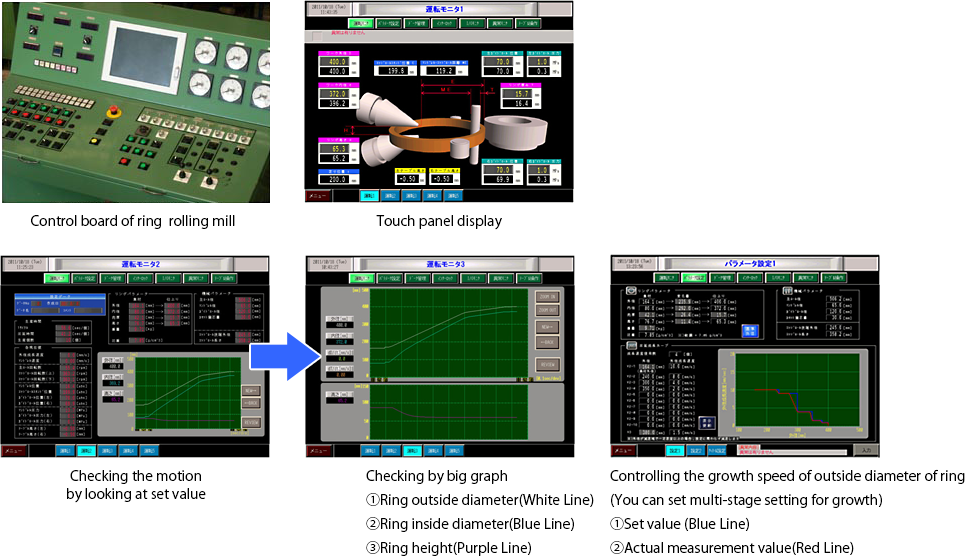

Rolling input value not requiring operator skill

It is fairly easy to for even an inexperienced operator to operate as the system controls the growth speed of ring outside diameter. The necessary input values for rolling ring forging products are mainly the growth speed of outside diameter, which means you can input the values for new type rings without past experience value.

You can set the values with multi-stage for the growth speed of outside diameter. The software enables you to fully utilize the motor power at initial stage of rolling. You can make rolling-forging products as initially set even if it was just one order.

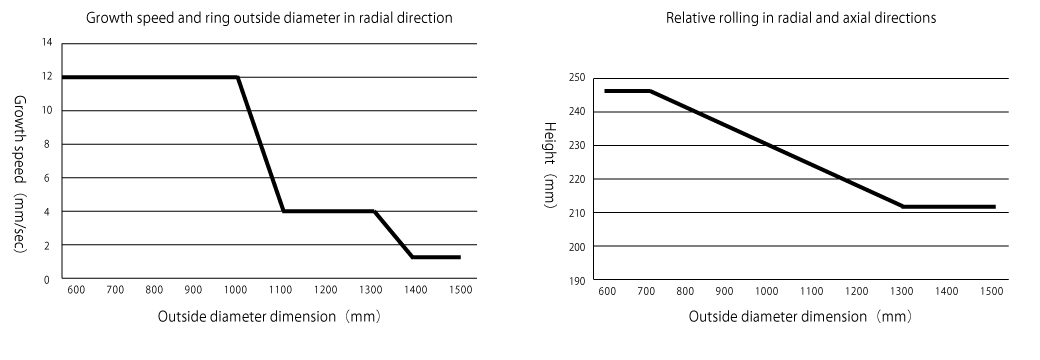

Besides, fishtail or depression in height direction, which generates with rolling in outside diameter direction, is prevented by rolling down with pressure according to the growth of outside diameter. The following shows the growth of outside diameter and height pressure down.

Allowance and tolerance of general ring forging products

| Machine finishing dimension | Rolling forging dimension | ||||

|---|---|---|---|---|---|

| OD(mm)×ID(mm)×Height(mm) | OD(mm)×ID(mm)×Height(mm) | ||||

| 1500 | 1300 | 200 | 1508 ±1.5 | 1292 ±1.5 | 208 ±1 |

| 1000 | 850 | 150 | 1007 ±1.5 | 843 -1.5,+1 | 158 ±1 |

| Machine finishing dimension | Rolling forging dimension | ||||

|---|---|---|---|---|---|

| OD(mm)×ID(mm)×Height(mm) | OD(mm)×ID(mm)×Height(mm) | ||||

| 1500 | 1300 | 80 | 1510 ±1.5 | 1290 ±1.5 | 90 ±1 |

| 1000 | 850 | 60 | 1010 ±1.5 | 840 -1.5,+1 | 70 ±1 |

Backword movement control of edge roll stand

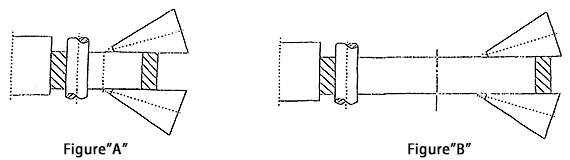

It is generally desirable that; the circumferential speed of ring edge surface and edge rolls are equal and; rolling is done as in the figure A for preventing the vibration of ring in rolling but it would not be realistic when rolling large diameter rings as it requires too long edge rolls.

Circumferential speed difference is solved by not matching to the speed of ring outside diameter in rolling but by matching the circumferential speed of edge roll to the position where ring thickness is and by making the sum of plus speed and minus speed zero.

Therefore, the problem of ring shake or the like caused by circumferential speed difference does not occur.

Also, large diameter ring is rolled with keeping the figure A to some diameter without making edging rolls too long redundantly. Edge roll stand moves backward like the following B figure after ring outside diameter grew to the edge of edging rolls. Hence, shaking or swelling which generates by the difference of circumferential speed between ring and edge roll does not occur.

Product Specification

| Type | KRM-400 | KRM-800 | KRM-1000 | KRM-1500 | KRM-2000 | KRM-3000 | KRM-4000 | |

|---|---|---|---|---|---|---|---|---|

| Ring Product | OD | 120~400mm | 200~800mm | 250~1000mm | 300~1500mm | 400~2000mm | 600~3000mm | 800~4000mm |

| ID | Min.110mm | Min.140mm | Min.180mm | Min.200mm | Min.230mm | Min.300mm | Min.400mm | |

| Height | 30~150mm | 40~300mm | 50~400mm | 50~500mm | 50~500mm | 50~600mm | 50~800mm | |

| Weight | Max.20kg | Max.150kg | Max.250kg | Max.500kg | Max.1500kg | Max.2500kg | Max.4000kg | |

| Rolling Power | Mandrel | Max.30ton | Max.60ton | Max.70ton | Max.80ton | Max.100ton | Max.120ton | Max.200ton |

| Edge roll | Max.20ton | Max.50ton | Max.70ton | Max.80ton | Max.100ton | Max.120ton | Max.200ton | |

| Motor | Main roll | 45KW | 110KW | 132KW | 160KW | 250KW | 315KW | 500KW |

| Edge roll | 22KW×2 | 55KW×2 | 75KW×2 | 90KW×2 | 160KW×2 | 200KW×2 | 315KW×2 | |