Hydro-Forming Press

Special Features

- Feature on Die

Only convex die is required. There is no need for hollow die. Convex die can be made of even plastic.

Tapered and parabolic drawn parts are produced in one forming operation while the classical drawing method generally requires 5 to 6 press operations and 1 to 2 intermediate annealing operations. - Feature on Products

Since the material thinning at the bottom radii is very small, thinner sheet metal can be formed.

An outstanding surface finish can be obtained because the sheet metal is drawn over a hydraulic cushion and not over the edges of a drawing die.

Excellent product shape can be obtained because pressure and speed can be set up according to forming condition.

No deformation after forming will break out. - Feature in Operation

This Hydroforming Press can be used as both of Double Action Deep Drawing Press and Single Action Deep Drawing Press (with Inner/Outer locked) when the Dome is put out of Press.

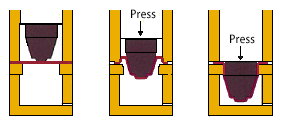

Basic Operation

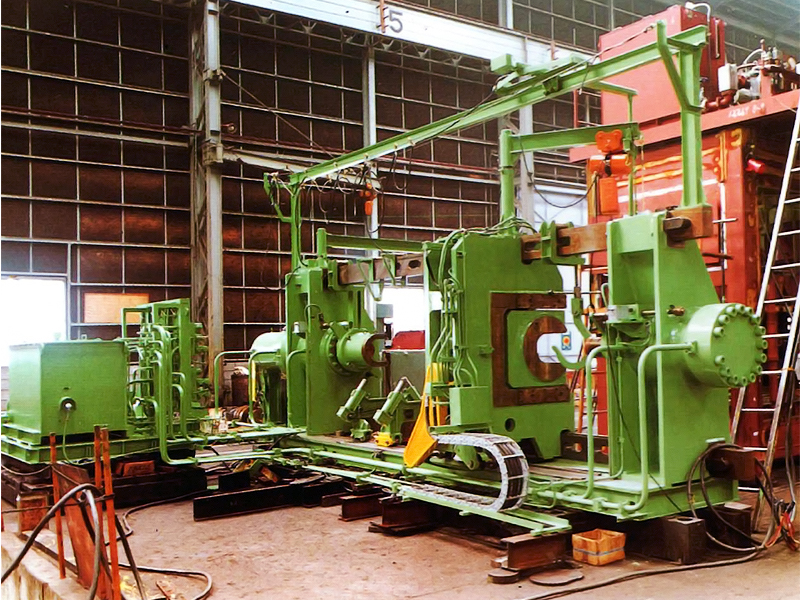

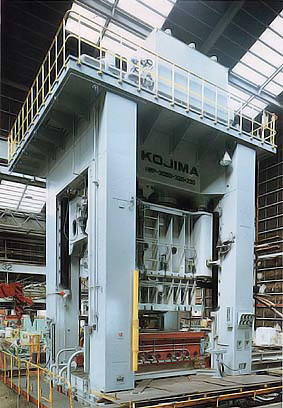

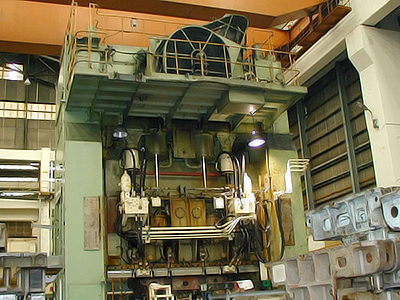

30000kN Hydro Forming Press

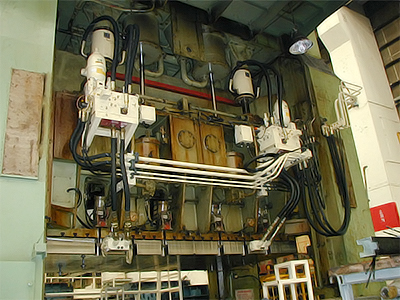

Forming Die in the Press

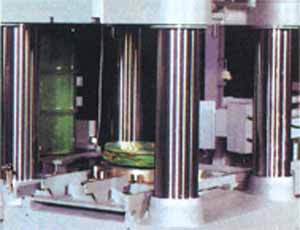

Building Material Forming Press

Special Features

- Such products as building panels and tiles, which are made of noninflammable materials, can obtain exceeding density, strength and flatness on surface with equal and high pressure by building Material forming Press.

- KOJIMA has business result of Building Material Forming Presses which capacity is up to 70000kN.

- KOJIMA will offer the most suitable high-quality press to production line. Standard, flat, wavy, embossed and other shaped boards are available. Conveyers and other accessories also are available.

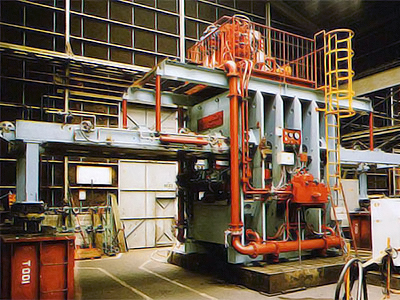

38000kN Building Material Press

and Traversing Equipment

12000kN Building Material Press

and Traversing Equipment/Ring Frame Type

Hybrid System

Lead Press in Tandem Line used to necessarily be Double Action Press. In accordance with the progress in Die mechanism and Die Cushion Device Single Action is getting to cover most of Deep Drawing Operation. Eventually Double Action Press is not necessarily required recently as lead presses for the saving of Dies cost and Maintenance cost.

Notwithstanding this situation Double Action Press can not be eliminated, because of its use for the forming of Service Parts and Special Parts, and are operated in Single Action use by using only inner ability to make most use of facility.

KOJIMA developed KOJIMA HYBRID PRESS SYSTEM in collaboration with Hyundai Motor Company (Seoul, Korea) in which both usage as Single Action and Double Action can be obtained by putting additional hydraulic system to Double Action Press.

Special Features

- Single Action mode will be available on Double Action Press by setting additional hydraulic device.

1.Full power of Inner and Outer can be utilized.

2.Maximum area of Slide can be utilized.

3.SPM remains the same as original specification. - Double Action mode is also available.

- SPM as a line will increase as Turnover Action is not required.

- Cost for remodeling is not expensive.

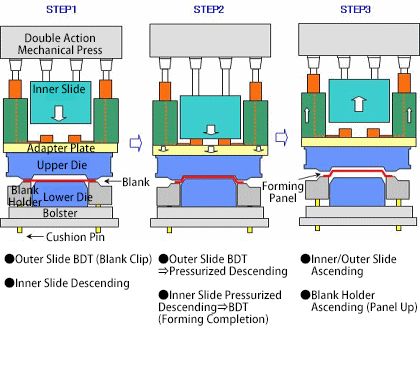

Slide Action and Drawing Sequence

Hyundai Motor Company/Ulsan

Hyundai Motor Company/Ulsan

Press Forming System(KIP)

This is a new Resin Forming system in which Vertical Type Press and Injection Machine are combined.

SP Mold Process (Multi Forming Process) which was developed by Sumitomo Chemical Co.,Ltd. is adopted.Integrated Molding Method of Surface and Base materials by use of Injection Press, instead of previous Extral Binding Process by separate molding, realized the great saving of labor and cost.This system is adopted as Lower Pressure and Lower Deformation method for following products.

- Inner and Outer parts of automobiles

- Large-sized industrial parts

- Household utensils

- Others

Special Features

- Simultaneous forming of Base and Surface materials

- Less forming process

- Shorter forming cycle

- Smaller equipment

- Cost saving

Incidental Device

The operation can be automated with following equipments.

- Resin Charging Device

- Surface Material Feeder

- Product Unloader

- Trimming Device

Forming Process

Products

FRP Molding Press

Special Features

- Parallel Control (Patent Pending) is to maintain the parallelism of slide by controlling four main cylinders. Four main cylinders can be controlled at any position of stroke at full pressure.

- The Slide is equipped with extra long eight-point-adjustable Gib Guides which can bear against off-center loading.

- The special shockless circuit realizes smooth operation.

- The pressing speed control system is available.

Incidental Device

The operation can be automated with following equipments.

- Material Cutting Machine

- Material Weighing Machine

- Die Shifter

- Material Charger

- Product Unloader

Charger

Unloader