Hydraulic Straightening Press

Click on the image to enlarge it.

Hydraulic Straightening Press

Our Steel Bar Straighteners will work on wide ranges of structural shapes, such as bars, I-beams and rails , and can handle any kind of distortion where the Roll Straighteners are not practical.

Special Features

- Our Steel Bar Straightener has high rigidity in order to support various heavy load and can endure in hard use for long years.

- The mandrels are of the special structure (patented) so that the steel bar with various curvature can be supported and be pressed without leaving the scar on the pressed steel bar.

- The front-rear workpiece rotating device and the conveyer are prepared for more effective straightening works.

- The connection with mill line is easy.

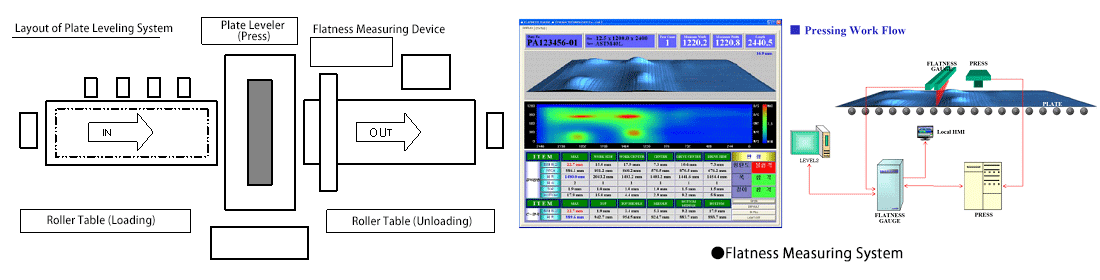

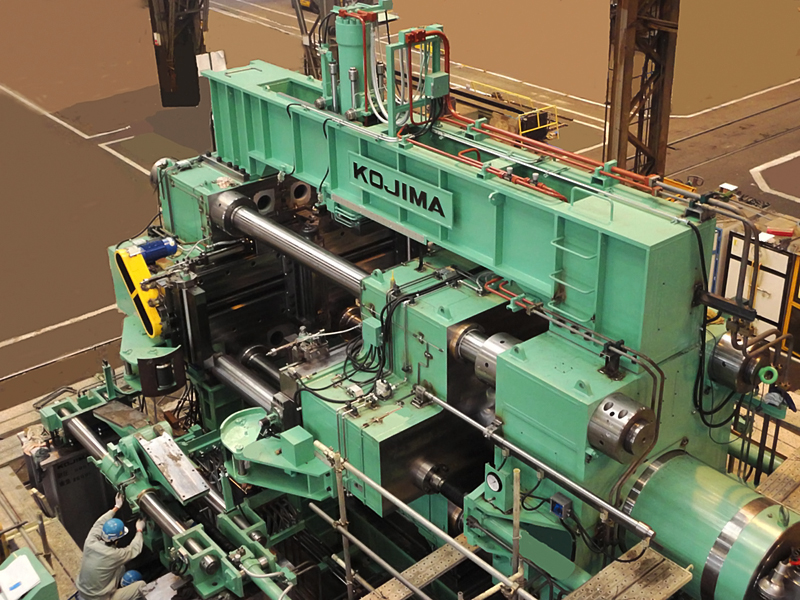

Plate Levering System

Plate Leveling System is the facility for modifying the flatness of Thick/ Semi-thick plate which is unloaded from Rolling Mill. This system is composed of Plate Leveler, Front/Back Roller Table (Option) and Flatness Measuring Device (Option).

3-Dementional Measurement for Steel Plate by Flatness Measuring System and High Usability by Plate Leveling System realizes the improvement of Flattening Operation.

Special Features

- Our Plate Leveler is Ram Head Traveling Type. Ram Head moves onto the flattening point to operate.

- High-Usability enables One-Man Operation.

- Front/Back Roller Table and Flatness Measuring Device are options for more efficient operation.